Introduction

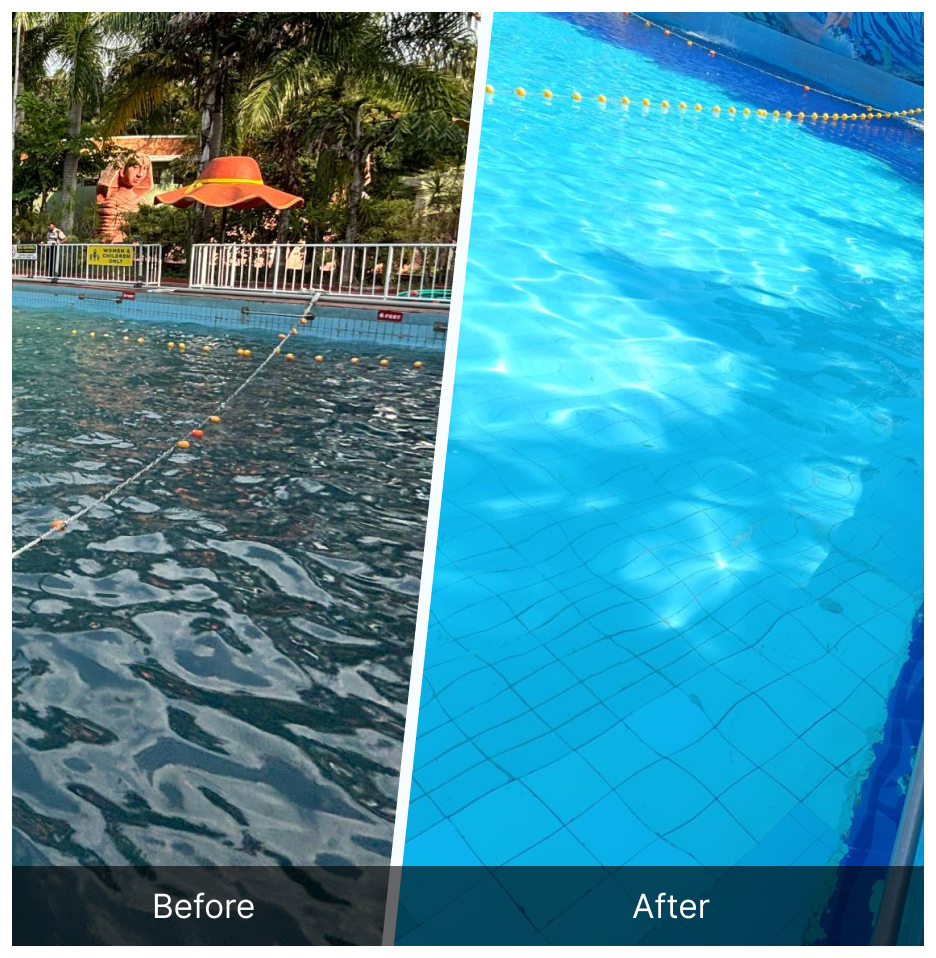

The water-tech industry faces one of the most complex challenges: dealing with the most precious, yet fragile resource on earth, WATER. Among the water resources, wave pools in water-themed parks present a unique chemical management challenge. Traditional manual dosing methods have long been the industry standard, but at what cost? This case study reveals how a renowned water theme park in India transformed its operations by embracing automation, proving that precision doesn’t just improve safety, it dramatically reduces chemical consumption, cuts operational costs, and elevates the guest experience to new heights.

The Challenge

Our client faced a range of challenges in the realm of wave pool management:

- Environmental Stewardship: India’s increasing commitment to environmental conservation necessitated a more sustainable and chemical-efficient approach to pool maintenance.

- Inefficient Chemical Dosing: Traditional manual dosing systems often led to inconsistent water chemistry, causing both chemical waste and potential risks to water quality due to over-dosing or under-dosing.

- Dynamic Water Conditions: Wave pools’ constantly changing conditions, from high-activity periods to quieter times, demanded a versatile solution capable of meeting variable chemical needs in real-time.

The Solution

In close partnership with our client, we introduced the Terra M Automatic Dosing System, a technological breakthrough that revolutionized their wave pool operations in multiple dimensions:

Real-Time Chemistry Management

The Terra M system continuously monitors water parameters, making micro-adjustments to maintain optimal chemical balance despite varying bather loads and activity levels. This intelligent approach eliminated the reactive nature of manual dosing that often resulted in correction overcorrections.

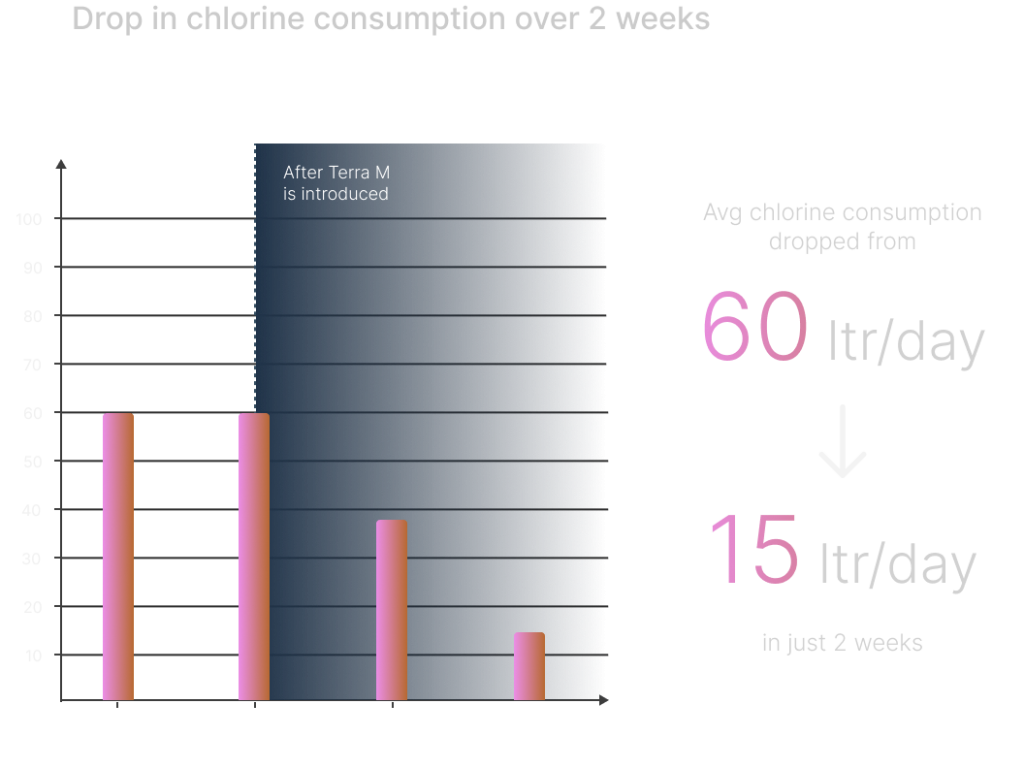

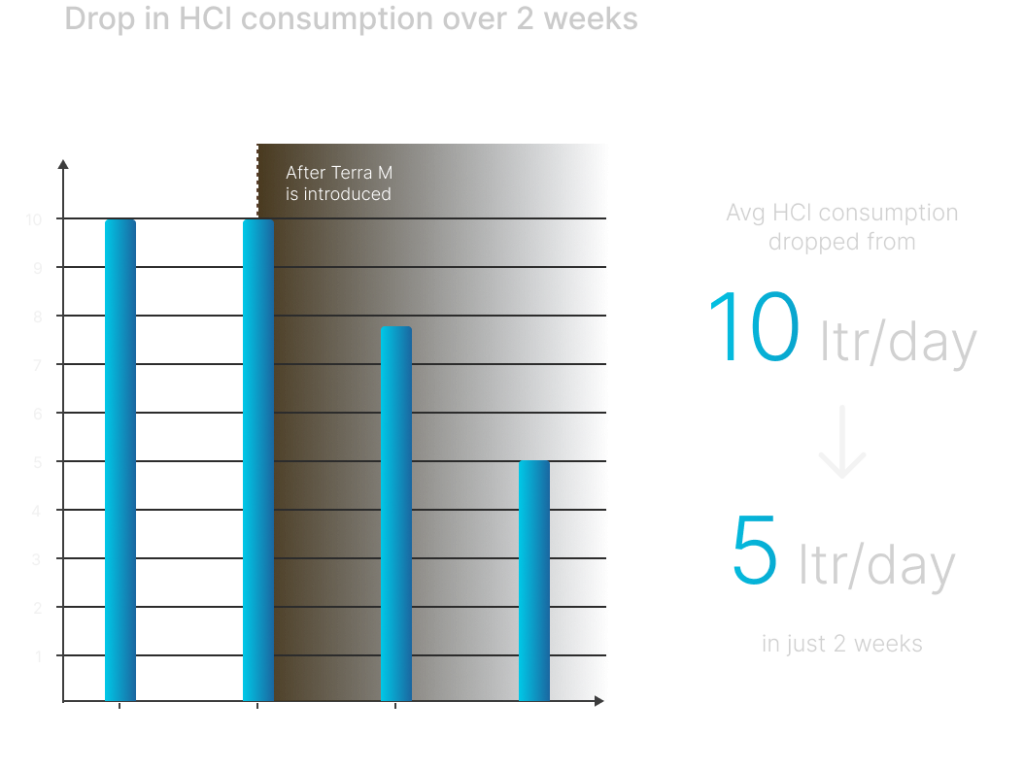

Chemical Consumption Transformation

Chlorine Efficiency: Consumption plummeted from 60 units to just 15 units within two weeks of implementation, a dramatic 75% reduction that demonstrates how precision dosing eliminates wasteful practices while maintaining proper sanitation.

HCL (Acid) Optimization: Daily usage dropped from 7-10 liters to approximately 5 liters, a 40-50% efficiency improvement that directly impacts operational costs and reduces chemical handling risks for staff.

Operational Excellence

The automated system freed staff from constant manual testing and adjustment routines, allowing them to focus on other critical guest service functions. Maintenance managers report spending 68% less time troubleshooting water quality issues, creating significant labor savings.

Return on Investment

The dramatic reduction in chemical usage generated a complete return on investment within just 5 months, far exceeding the client’s 12-month ROI target. Ongoing savings continue to contribute directly to the park’s profitability while simultaneously improving the guest experience.

Future-Ready Operations

With comprehensive data logging and trend analysis capabilities, the facility can now make evidence-based decisions about operational patterns, preventative maintenance, and further optimization opportunities, transforming water chemistry management from an art to a science.

Reduced Water Footprint in the Water Theme Park:

Often chemical overdosing will lead to water addition from the balancing tank for ppm adjustment. However, with flawless dosing potential, Terra M ensured that water usage is optimum, thus helping the client reduce the water footprint.